The LS reluctor wheel, also known as a tone ring or trigger wheel, is a critical component mounted on the rear of GM LS-series crankshafts. The magnet reads the teeth of the reluctor wheel to generate signals for the ECU. It’s read by a magnetic sensor to provide the engine control unit (ECU) with the precise crankshaft position and speed that governs ignition timing, injection, and overall engine performance. Wheels ID (identification) is important to ensure the correct reluctor wheel is matched to the appropriate ECU, as 24x and 58x wheels require different control strategies. The reluctor wheel plays a vital role in providing the ECU with accurate crankshaft position data, which is essential for proper engine operation.

Introduction to the Reluctor Wheel

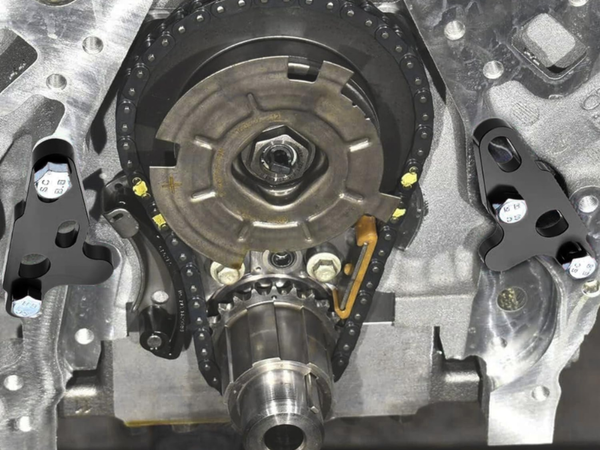

The reluctor wheel—also known as the tone ring or timing wheel—is a foundational part of every LS engine’s ignition and fuel management system. Mounted securely on the back of the crankshaft, this wheel works in tandem with a magnetic sensor located outside the engine block, near the starter. As the engine turns, the reluctor wheel’s teeth pass by the sensor, generating signals that the ECU uses to determine the exact position and speed of the crankshaft. This precise data is essential for controlling ignition timing and fuel injection, ensuring smooth operation and optimal performance. In this section, we’ll explore the design, materials, and maintenance of reluctor wheels, as well as what’s involved in swapping them for different applications.

LS Engine Overview

LS engines are split into two main generations—Gen III and Gen IV—each with its approach to crankshaft position sensing. Gen III engines are equipped with a 24x reluctor wheel, while Gen IV engines use a 58x reluctor wheel for even more precise crank position data. The crankshaft sensor, which reads the reluctor wheel, is color-coded for easy identification: black sensors are paired with 24 teeth wheels, and gray sensors with 58 teeth wheels. Understanding these differences is crucial when working on engine swaps or modifications, as using the correct reluctor wheel and sensor combination ensures the ECU receives accurate information for reliable engine operation.

Reluctor Wheel Design

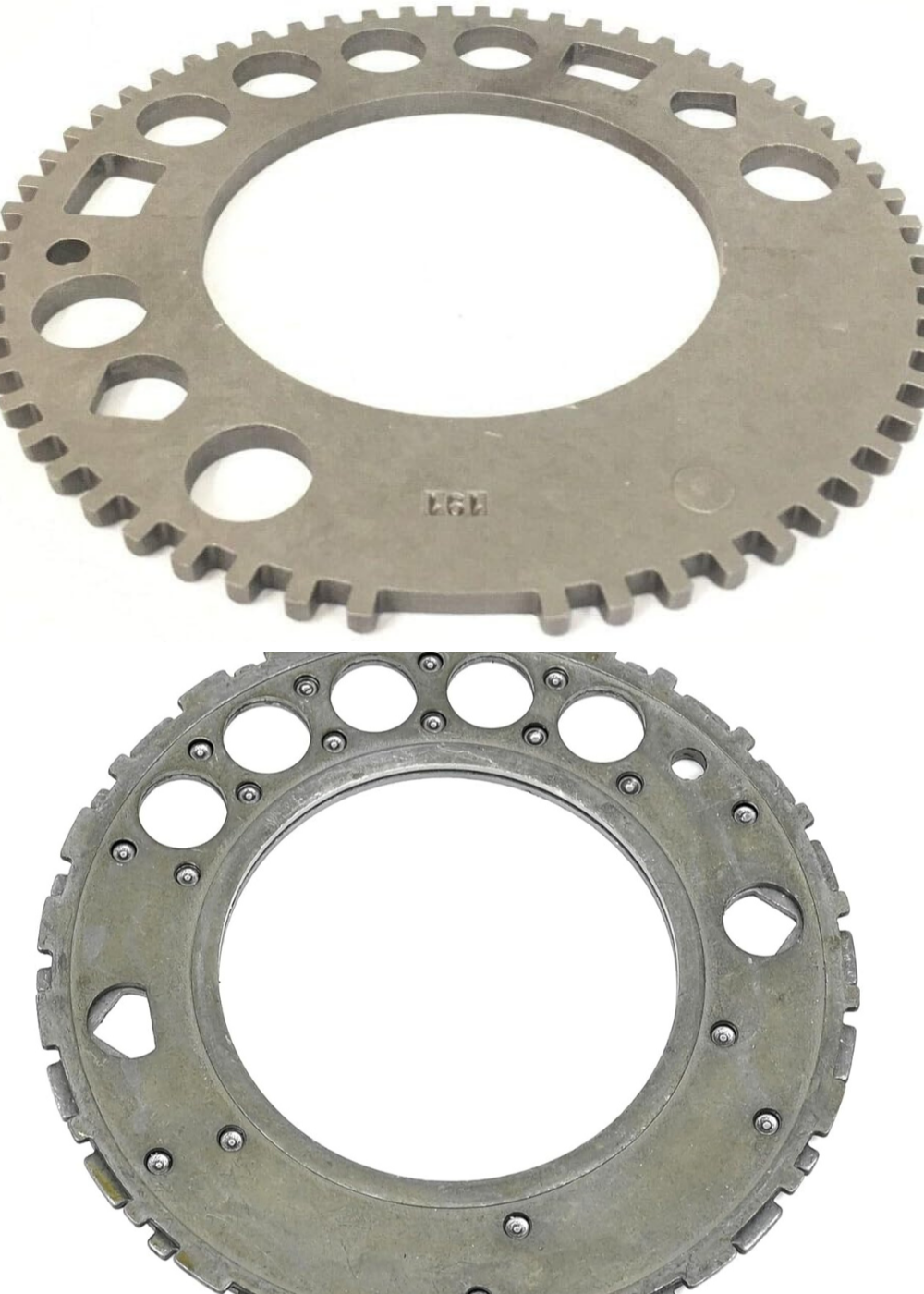

The design of the reluctor wheel is central to its function in providing the ECU with precise crankshaft position data. Each wheel features a series of evenly spaced teeth that pass by the magnetic sensor as the crankshaft rotates. Gen III engines use a 24x reluctor wheel with 24 teeth, while Gen IV engines utilize a 58x reluctor wheel with 58 teeth. The higher tooth count in the 58x design allows for finer resolution, giving the ECU more detailed information and enabling better engine performance and efficiency. The reluctor wheel is mounted to the crankshaft using an interference fit, which means it must be installed and removed with care to avoid damaging either the wheel or the crankshaft itself.

Reluctor Wheel Materials

Reluctor wheels are engineered from robust materials like steel or aluminum to withstand the demanding environment inside an engine. The 24x reluctor wheel, commonly found in Gen III engines, is a two-piece assembly with plates tack-welded together for added strength. However, it’s important to note that heating these wheels during removal or installation can weaken the welds, making it risky to reuse a 24x reluctor wheel. For this reason, new reluctor wheels are recommended for any installation or swap, as they are both affordable and reliable. The choice of materials ensures that reluctor wheels can handle high rotational speeds, temperature fluctuations, and the stresses of daily engine operation.

Types of LS Reluctor Wheels: 24x vs 58x

- 24x Reluctor (Gen III & Early Gen IV)

- Features 24 teeth and is a two-piece ring. This is considered the old reluctor design.

- Found on LS1, LS6, LQ4, and early LS2 engines (1997–2005/6) (HOT ROD).

- 58x Reluctor (Later Gen IV)

- Offers 58 uniformly spaced teeth for higher resolution signals. This is the newer style used in Gen IV versions.

- Used on LS3, LS7, LS9, and later LS2 engines (post-2006) (HOT ROD).

Gen IV versions use the newer style 58x reluctor, while earlier engines use the old reluctor.

Why It Matters

Your ECU is calibrated for a specific tooth count:

- 24x wheels deliver coarser data, used by earlier engine control units, and the engine's ECU is calibrated for this specific reluctor wheel.

- 58x wheels offer finer resolution for modern ECUs.

Using the wrong reluctor wheel affects swapping and can lead to timing and performance issues. Mixing them up can cause misfires, check-engine lights, or no-start conditions unless you’re using a programmable tuning system (HOT ROD). Higher end ecus may allow more flexibility when swapping reluctor wheels, but proper matching is still crucial.

How to Identify Which Wheel You Have

Methods include:

- Count the teeth: simply count if visible.

- Sensor color: black = 24x; gray = 58x (YouTube, HOT ROD).

- ECU era: pre-2006 = 24x, post-2006 = 58x, with exceptions (Motor Vehicle Maintenance Stack Exchange).

- Cam sensor location:

- 24x typically have the cam sensor behind the intake.

- 58x engines locate it in the front timing cover (HOT ROD).

- Look for precise marks or notches: Some reluctor wheels have precise marks or notches that help with identification and alignment.

- Check for entry hole or indexing hole: Certain reluctor wheels feature an entry hole or indexing hole to assist with proper alignment during installation and to help identify the type.

Installing or Swapping Reluctor Wheels

Changing these is a press-fit operation:

- Begin with the heating process: Apply a little heat or less heat to the reluctor wheel, depending on the reluctor type, and heat the ring to about 200–450 °F for easy, safe installation (HOT ROD). As the wheel expands, it will fit more easily onto the crankshaft. The reluctor rides on the crankshaft, and the two plates of the 24x reluctor must be handled carefully during this step.

- The reluctor wheel must be properly indexed to the crank flange or the crank's flange, and square alignment is critical to ensure accurate timing. Using a cold reluctor or attempting a cold press can cause damage to the wheel or crank.

- Use a proper installation jig to ensure exact indexing—crucial for timing (HOT ROD, MotorTrend). Employ the internal guide pin and jig's ring for precise alignment, and make sure the jig is removed (jig removed) after installation.

- To seat the wheel, use a dead blow hammer, small hammer, or improvised energy transfer device to apply a few light taps, a few persuasive taps, or persuasive taps. The wheel should be lightly chambered, and the wheel cleared after installation to avoid any interference.

- Avoid hammering cold rings warp easily, causing timing errors (HOT ROD).

Tip: Here are a few tricks for successful installation: check for precise marks, use the entry hole or indexing hole, and ensure the reluctor meets the crank's flywheel flange for proper fit.

When You May Need to Swap

- Engine swaps into older vehicles: e.g., putting an LS3 in a chassis designed for 24x triggers.

- A damaged reluctor is a common reason for swapping the reluctor wheel, as bending or warping can occur during removal or installation.

- The factory LS crank, replete with its original reluctor, may require replacement or upgrade for certain applications, especially to ensure compatibility with the engine management system.

- The Lingenfelter TRG‑002 module can adapt a 58x LS into a 24x system without rebuilding (lingenfelter.com).

- Upgrading ECUs or using standalone systems may also require matching the appropriate wheel.

Reluctor Wheel Maintenance

Maintaining your reluctor wheel is key to preventing timing issues and ensuring your engine runs smoothly. Regular inspection for signs of wear, damage, or debris buildup can help you catch problems early, such as reluctor wheel slips or damaged reluctors, which can lead to inaccurate crank position info and engine performance issues. When replacing or swapping reluctor wheels, always use the correct installation tools and procedures—such as a specialized jig for precise alignment and heat for proper interference fit—to avoid damaging the wheel or crankshaft. Keeping the reluctor wheel clean and securely mounted will help your engine’s ECU receive accurate data, reducing the risk of misfires or other timing-related problems. By prioritizing reluctor wheel maintenance, you’ll help ensure the long-term reliability and performance of your LS engine.

JEGS 50248 LS Crankshaft Reluctor Wheel, 24 Tooth

- 1997-2005 LS Engines

- 24-Tooth

Michigan Motorsports 24X Crankshaft Reluctor Wheel Fits 4.8 5.3 5.7 6.0 LS1 LS2 LS6 L33 LM7 12559353

- 24X Crankshaft Reluctor Wheel

- GM #12559353

- The 24x design offers high-resolution timing information, making for enhanced power and optimized fuel efficiency

- 24X Reluctor wheels were primarily used on 1997-2005, and some 2006 models

- Double-check by looking at the Crankshaft Sensor. All 24x wheels are detected by a black crankshaft sensor, while 58x use a grey sensor. This sensor is located at the back of the block, near the oil pan, on the passenger side of the engine, just above the starter.

Michigan Motorsports 58X Crankshaft Reluctor Wheel Fitment for GM 12586768 -Fits LS2 LS3 L76 L98 LY6 LS4 4.8L 5.3L 5.7L 6.0L 58 T

- 58X Crankshaft Reluctor Wheel

- Replacement for GM 12586768

- 58X Reluctor wheels were primarily used on 2006+ GM Vehicles.

- Most 58x use a grey crankshaft sensor

- This sensor is located at the back of the block, near the oil pan, on the passenger side of the engine, just above the starter.

GM 58X Tooth Crankshaft Reluctor Wheel Exciter Ring 4.8L 5.3L 6.0L 6.2L LS2 LS3 L76 L98 LY6 LS4

- BRAND NEW GM OLD STOCK

- GENUINE OEM QUALITY

- GM PART #: 12586768

Chevrolet Performance 12559353 Crankshaft Reluctor Wheel

- 24-Tooth

- 1997-2005 LS Engines

FAQs

How do I tell if I have a 24x or 58x reluctor wheel?

Look at the sensor—black equals 24x, gray equals 58x—or count the teeth and note your engine’s model year

Can I install the wheel cold?

No. Heating is essential to avoid warping; cold pressing or hammering risks damage

Is switching between 24x and 58x a DIY job?

It can be, with the right tools: a heat source, an installation jig, and patience. Or consider having a machine shop handle it

What is the purpose of those odd notches on the 24x ring?

They create missing or long pulses for the crank sensor, providing a zero-reference signal for the ECU

Final Thoughts

The LS reluctor wheel is a small but crucial link in engine timing and performance. Whether you're swapping engines, upgrading the ECU, or troubleshooting crank sensor issues, matching your trigger wheel (24x or 58x) to your ECU is non-negotiable. Use heat and a jig for installation, and your LS engine will run smoothly and reliably. Order today!